Your Trusted Scrap Metal Recycling Machines Manufacturers In China

Your Dedicated Partner Of The Scrap Metal Recycling Solutions

Heavy Duty Metal Scrap Gantry Shear Cutting Machines

The QK91Y series heavy duty metal scrap gantry shear cutting machines are used for cutting waste metal, which are developed

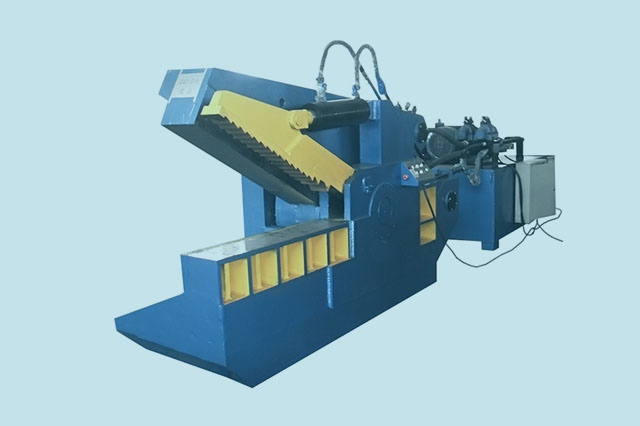

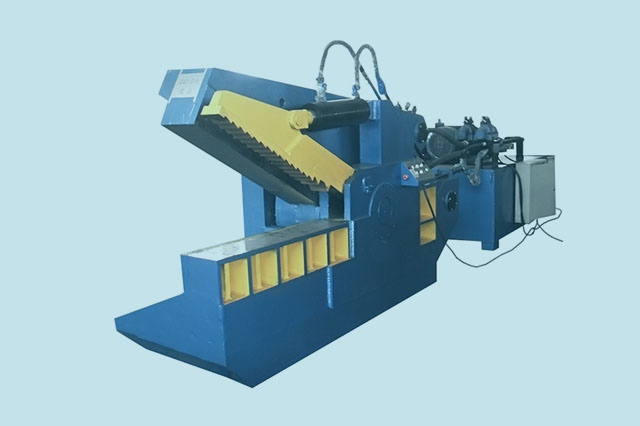

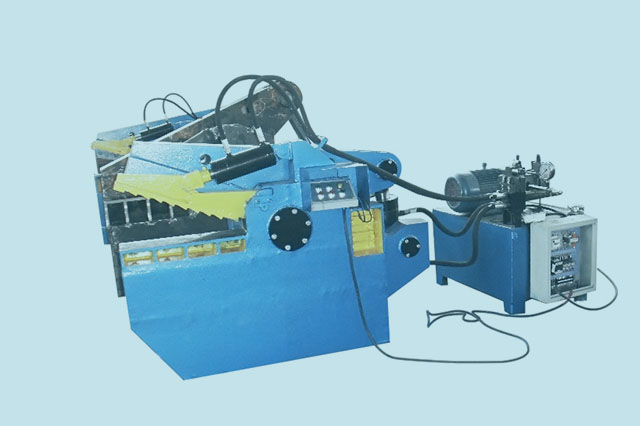

Hydraulic Alligator Shear For Sale

The hydraulic alligator shears are applied in recycling companies, automobile dismantling plants, smelting and casting industry to cold-shear section steel

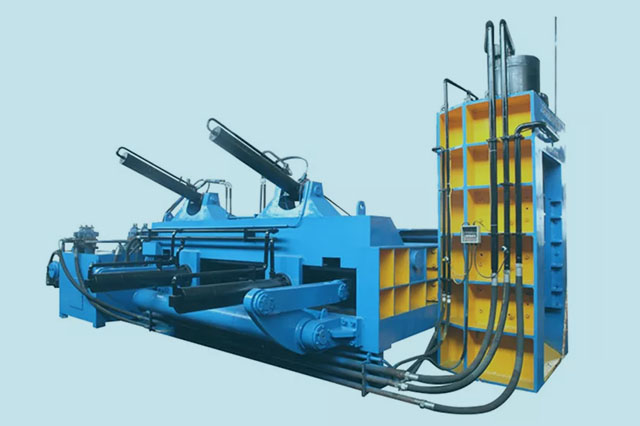

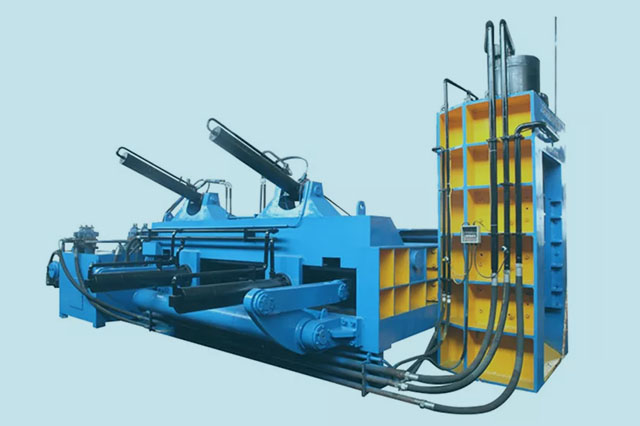

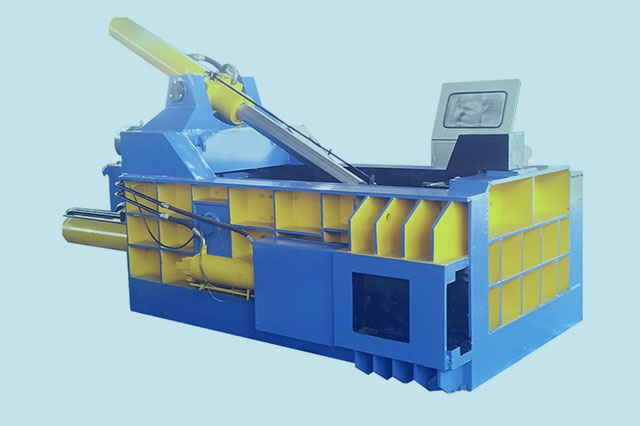

Forward Push Out Scrap Metal Balers Machines

Y81Q series hydraulic forward push out scrap metal balers machines are capable of extruding various metal leftover, steel paring, waste

Y81F series hydraulic turnover scrap metal balers press the leftover of all kinds of metal material, including steel shavings, scrap

Featured Products

- All

- Metal Balers Machines

- Metal Briquetting Machines

- Metal Shearing Machines

Heavy Duty Metal Scrap Gantry Shear Cutting Machines

Hydraulic Alligator Shear For Sale

Forward Push Out Scrap Metal Balers Machines

Turnover Scrap Metal Balers

Push Out Metal Scrap Baling Machines

Metal Chips Briquetting Machines

Aluminum Chip Briquetters

Hydraulic Scrap Metal Alligator Shearing Machines

Masters In Metal Balers And Recycling Machines Manufacturing

As a leading scrap metal recycling machines manufacturer, Highv has rich experience manufacturing high quality metal balers machines and recycling machines for hundreds of industries worldwide. We are top leader hydraulic metal balers machines factory, scrap metal briquetting and shearing machines suppliers.

We have a professional and efficient engineers team that will handle all your metal recycling goods from China. Just ask for a quick quote, whether you are already our client or not, we will be available online 24/7 to support your project.

- OEM/ODM

- Fast Delivery

- 30 Years' Industry Experience

- Advanced Technology

- 24/7 Technical Support And Service

- SGS, IOS9000

More Than An Manufacturer...

As An Manufacturer

We have rich experience in designing and producing hydraulic scrap metal balers and metal recycling equipment. Therefore, customers can recieve competitive quotation from us. In addition, we built a good production management system to ensure that every order is produced on time and accurately.

As An Exporter

Thanks to good relationship, we can get the best products and prices from other components manufacturers. At the same time, our engineers team can help you to carry out product-testing and assembly, we can also help you inspect other factories, ensure the quality, and deliver cargo for you on time.

24/7 Technical Support & Customer Service

Whenever You Need us, We Are Here Waiting For You

Get All Resources About Scrap Metal Recycling Solutions

How To Install And Use AutoCAD For Metal Baling Machines Design?

AutoCAD is software for 2D and 3D computer-aided design. Developed by Autodesk, AutoCAD is a commercial software application first released in 1992. It is becoming more

How To Install And Use SolidWorks For Metal Balers Machines Design?

SolidWorks is a powerful design and analysis program software. If you need some rudimentary 3D modeling, SolidWorks, like most professional design software, is much more

6 Factors Related Hydraulic Metal Balers Selection: Beginner’s Guide

These hydraulic metal balers machines can cold compresses waste automatic shells, waste buckets, waste copper and aluminum into rectangle lumps. Learning more about hydraulic metal balers selection

Industries We Serve!

Our high quality metal recycling machine is mainly used in steel plants, recyling corportation, waste recovery and metal refining industry.

See Why Our Customers Love Us

Dear all, we have received scrap metal balers and helped finish the installation smoothly. They works very well! Thanks again for your team cooperation!

Company Owner

Hello, Jack! Thank you for your efforts, everything is fine. Please forward my thanks and appreciation to your team! They did a fantastic job!

Purchasing Manager

request a quote

Frequently Asked Questions

- Consult: We will recommend the right models of hydraulic scrap metal balers machines to you after being informed by your requirements.

- Quotation: We will supply you with our detail quotation according to our consulted metal balers machines with the best quality and price.

- Process Evaluation: Buyers and our Highv team engineers carefully evaluate and discuss all the details of the order to exclude any misunderstanding.

- Placing The Order: If you have no doubts, we will send you the proforma invoice, and then we will sign a sales contract for your reference.

- Production: We will arrange the new production as soon as receiving your signed sales contract and deposit payment. The updated news about metal balers machines production will be sent and informed to the buyer during the production period.

- Inspection: The whole production procedure will be under regular inspection and strict quality control. The complete metal balers machines will be tested to make sure they can work very well before shipment.

- Delivery: We will arrange the delivery as the related terms in the contract after the confirmation by the buyer.

- Custom Clearance: We will supply and deliver all the metal balers machines shipping documents to the buyer and ensure a smooth customs clearance when import.

- Technical Support and Service: We will offer 24/7 professional technical support and service for every buyer. Email us or call us any time, any day. We’ll have your problem fixed in short time.

As a top scrap metal baling machines and recycling equipment manufacturer in the world, here we promise:

1. 12 months for all sold scrap metal baling machines and recycling equipment.

2. Long life-time maintenance, our professional team will offer 24/7 online technical support.

3. Except the damage artificially, we are responsible for offering the fittings and parts free of charge during warranty period.

4. After the warranty period expired, you only need to pay the actual maintenance cost.

5. Certificate support: ISO, SGS.

The metal chips briquetting machines can compress and pack the aluminum chip, steel chip, iron chip, and copper chips for melting down.

It can replace the waste steel, pig iron, aluminum ingot and waste copper as raw materials and reduce the fire loss.

This equipment can press coldly the cast iron chip, steel chip, copper chip and aluminum chip into 3~6 kg cylinder caky blocks, easy for transportation, furnace casting.

We can help estimate the shipping cost for your hydraulic scrap metal alligator shearing machines products.

Please note, customs fees and additional fees may apply for global shipments. Please contact your local customs agents for more information about detailed fees.

If you want to get the final price (such as contract amount, China local fees, shipping cost).

Please contact us to get a free quotation, we’ll calculate the final price of the required hydraulic scrap metal alligator shearing machines.

The spirit of our company is that safety is the foundation of production and quality makes customers. We pay more attention to quality support, supply scope, inspection, testing standard, shipment packing, after-sales service.

We have passed ISO quality management system certification.

At the same time, we will help take photos and shoot debugging videos for you if you need.

Every scrap metal baler and recycling machine product will be fully assembled and carefully tested before packing and shipping.

The QK91Y series heavy duty metal scrap gantry shear cutting machines are used for cutting waste metal, which are developed to meet the market demand.

It is used to produce and process various kinds of steel, such as channel steel, steel pipe, aluminum material and other heavy scrap steel.

The material after cutting has many advantages, such as improving smelting quality, reducing smelting cost and reducing material transportation cost.

- The easiest way to find the best metal recycling machines factories and suppliers in China is by searching " [metal recycling machines]+suppliers China" from Google.

- Your metal recycling machines suppliers should provide you the best scrap metal recycling solution as soon as possible.

- Your metal recycling machines suppliers should provide most competitive price and good service to support your projects.

What Are The Applications of Y81 Series Scrap Metal Balers Machines?

Y81 series scrap metal balers machines press the leftover of all kinds of metal material, including steel shavings, scrap tel, scrap aluminum, scrap copper, scrap stainless steel to be qualified in the shape of cuboid, octagon, cylinder and so on, which not only decreases the speed of casting.

This machine is mainly applicable to steel mills, recycling industries and ferrous metallurgical works.

Compression box size, bale size, bale shape can be customized according to clients requirement.

What Are The Applications of Y83 Series Metal Chips Briquetting Press Machines?

The Y83 series metal chips briquetting press machines are suitable for aluminum alloy factory, steel casting factory, aluminum casting factory, copper casting factory, etc.

To compress and pack the aluminum chip, steel chip, iron chip, and copper chips for melting down.

It can replace the waste steel, pig iron, aluminum ingot and waste copper as raw materials and reduce the fire loss.

This equipment can press coldly the cast iron chip, steel chip, copper chip and aluminum chip into 3~6 kg cylinder caky blocks, easy for transportation, furnace casting.

After the iron chip has been pressed, the densities reach 5 ~ 6T/m³.

The machine can also adopt the domestic and imported hydraulic elements and electric components fitted with automatic feeding, weighing and other devices.

Which Y83-500 hydraulic metal scrap briquetting plant for copper design, briquette density reaches over 7T/m³, is ideal to press and pack the lead and brass ideal products.

What Are The Applications of Q43 Series Hydraulic Scrap Metal Alligator Shearing Machines?

Q43 series hydraulic scrap metal alligator shearing machines are applied in recycling companies, automobile dismantling plants, smelting and casting industries to cold shear all shapes of profile steels and all kinds of metal into qualified furnace feed materials.

What Are The Applications of QK91Y Series Heavy Duty Metal Scrap Gantry Shear Cutting Machines?

The QK91Y series heavy duty metal scrap gantry shear cutting machines are suitable for the steel plants, recycling companies, ferrous and non-ferrous metal smelting industry to compress metal scrap (steel parings, waste steel, waste copper and aluminum, waste stainless steel, scrap from discarded automobiles) into acceptable furnace charges of cuboids, so as to reduce the cost of transportation and smelting, to speed up furnace charging. Then cut the bale after baled into pieces.

How To Choose Your Y81 Series Hydraulic Metal Scrap Baling Machines Correctly?

- If your scrap material is scrap metals, non-ferrous metals, color metals, we will recommend Y81F series metal baler for you, which has high pressing force with bales tilting out design.

- If your scrap material is light weight metals, such as scrap aluminium, scrap copper, tin cans, buckets, we recommend our Y81Q series metal baler for you, the bales will be pushed from baler forward.

- If your scrap material is heavy metals, then we recommend our Y81T series metal balers for you, the bales will be pushed out from the side of the metal baler.

Why Recycle Waste Aluminum Cans With The Hydraulic Aluminum Cans Balers?

Aluminum is a very valuable metal resource on the earth, and it is also widely used in our life.

Recycling waste aluminum cans are often more valuable than normal scrap iron cans.

The price of aluminum can reach more than 3,000 USD per ton, while the price of iron is less than 1,500 USD per ton.

Because the composition of the scrap iron can is complicated, tin and zinc are often plated on it, and the cost of refining is also high.

Aluminum in the composition of aluminum cans is much purer, and it is easy to recycle and refine again.

In the process of recycling and processing waste aluminum cans in large quantities, hydraulic aluminum can balers machines are widely used in this field.

How Does Hydraulic Scrap Metal Alligator Shearing Machine Work?

When the cut steel bar falls into the receiving frame, due to the spring action, the cutter head will generally return to the original position.

This is the basic working process of the shear.

Firstly, the steel base materials of different materials are the most basic influencing factors.

For the shear equipment, even for the same material, if the components of the materials are different, the cutting accuracy will be different.

Secondly, the influence of different diameter of steel base material on the cutting accuracy can not be ignored, because the allowable cutting accuracy deviation of different diameter steel bars is completely different.

In addition, the processing accuracy of steel bars required by different construction sites will also be different, which is also one of the factors affecting the shear accuracy of head.

In fact, when the operators actually operate this kind of equipment, the work effect between skilled and unskilled employees will also be very different, which is directly related to the cutting accuracy of the shear.

Turn on the power supply, the high-pressure oil pump will work immediately, and the oil will enter the rear cavity of the working cylinder.

LOOKING FOR SOLUTIONS IN SCRAP METAL RECYCLING INDUSTRY